High-Reliability FAQ

Frequently asked questions about high-rel products and testing

What is the difference between Qualification and Group C Testing?

Qualification is done to validate the initial component capability to meet the critical specification requirements, Group C Testing is done to validate whether a given component manufactured lot meets the critical specification requirements.

What does EM stand for?

EM stands for Engineering Models. Engineering Models are shipped with a C of C only.

What is the difference between a slow blow fuse and a fast-acting fuse?

A slow blow fuse is different from a fast-acting fuse in its capability to withstand transient pulse currents, i.e., it can withstand the surge current upon power-on/off, thus ensuring the equipment works normally. For this reason, slow blow fuses are often called time-delay fuses. Technically, a slow blow fuse features a higher I2t value, and it requires more energy to blow, so it is more capable of withstanding pulses compared to a fast-acting fuse of the same rated current.

What is the standard screening for flight fuses?

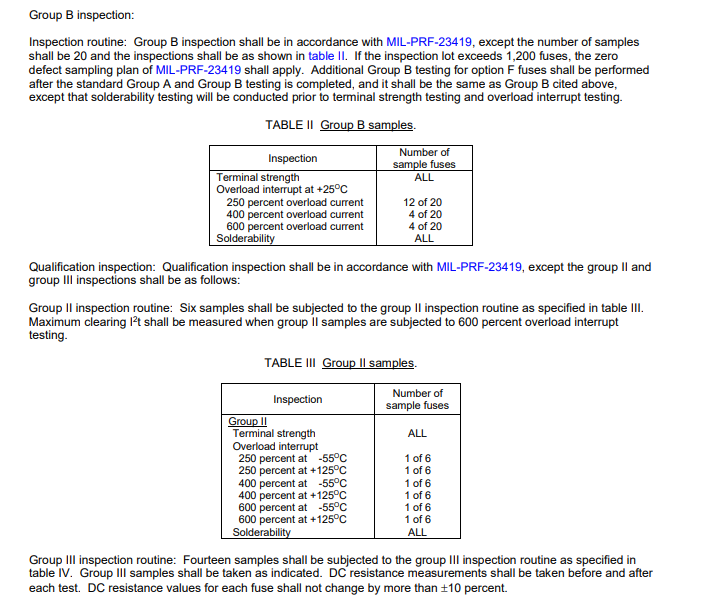

Group B Testing as per MIL-PRF-23419/12F:

What does fuse Group “C” Testing entail?

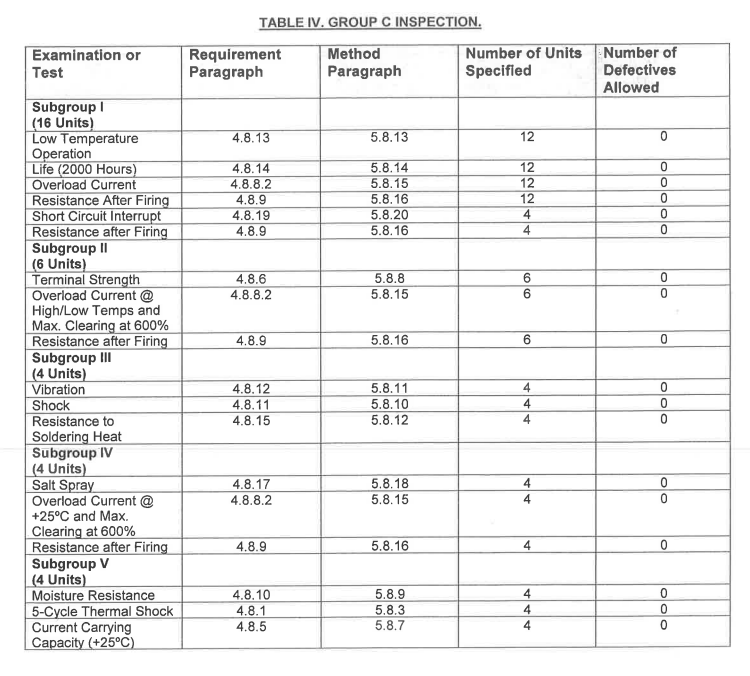

Group C inspection: Group C inspection shall be in accordance with MIL-PRF-23419, except 16 samples shall be subjected to the subgroup I inspections as specified in table V. Maximum clearing I2t for subgroups II and IV shall be performed at 600 percent of the +25°C rated current.

What is the difference between the P700L and the P700LH?

The "H" designation signifies that a high temperature solder has been used in the manufacture of the fuse.

Where can I see blow curves or STEP files for high-rel products?

Please reach out to our Applications Engineer for information on STEP files.

If we do not have these files available already, we can create certain files at the request of customers.

Where can I find the frequency curves for the Hi-Rel ferrite chip beads?

Frequency curves for the HRB can be found here.

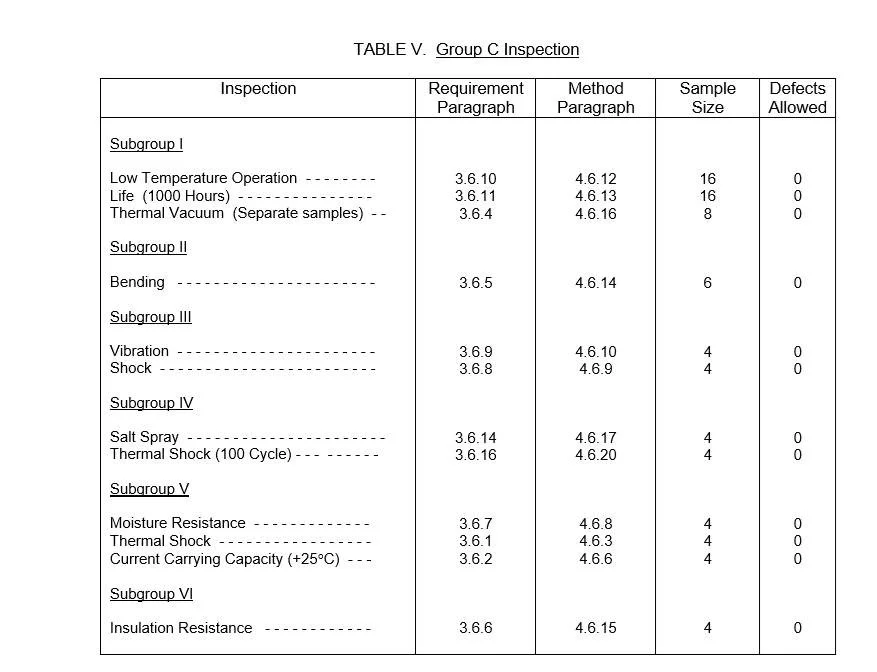

What does HRB Group “C” Testing entail?

What does “-US” stand for?

"-US" parts are up-screened parts.

What testing do you do to ensure HRB-US parts are qualified?

Finished HRB-US products are up-screened to DSCC 03024 specifications.

Can you describe your solder dipping process?

AEM’s Tin Whisker Mitigation (TWM) process is done by adding lead (Pb) to components with pure tin (Sn) terminals. Our Sn-Pb conversion process involves both Sn-Pb plating and subsequent fusion processing to ensure that the resultant component terminations are a homogenous mixture of Sn-Pb. The AEM Sn-Pb conversion process is NOT a hot solder dip operation that introduces the risk of thermal shock to the components.

Are AEM Hi-Rel beads ESD sensitive?

No, AEM HRB/DLA 03024 components are not ESD sensitive.

Are AEM Hi-Rel components moisture sensitive?

All AEM Hi-Rel Fuses and Hi-Rel Beads (HRB/03024 types) products are rated MSL-1 (not moisture sensitive).

What is the maximum rated voltage for high-reliability chip bead (HRB) products?

Ferrite chip beads are DC current sensitive and not voltage sensitive from an operational perspective. All electrode layers within a ferrite chip bead including AEM’s HRB/03024 series components are at the same voltage potential. The rated DC current should not be exceeded for steady state operating conditions.

Note that Dielectric Withstanding Voltage (DWV) testing is conducted during Group C Testing per MIL-STD-202-302 (Condition A) with 100V applied between the ferrite body and terminals. DWV testing does not represent a condition we would expect during normal operation, but it does provide one aspect of voltage rating, at least in terms of DWV.